Types of Molds Used in Rotational Molding

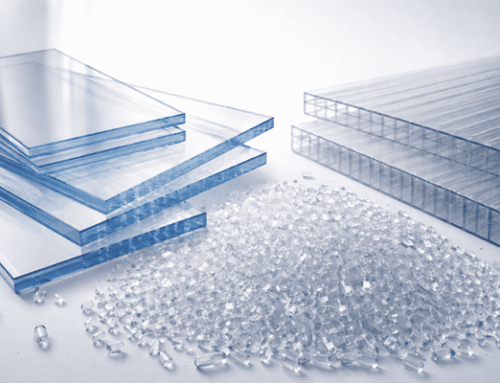

The success of any rotationally molded part begins with the right rotational mold. Because the process relies on resin evenly coating the interior surface during rotation, mold design and material selection are critical for part quality, durability, and production efficiency.

There are three primary types of molds commonly used in rotational molding:

Cast Aluminum Molds

These are the most widely used molds in the industry, known for their ability to capture fine detail and produce consistent parts. Cast aluminum offers excellent heat transfer, relatively low cost compared to other tooling, and the flexibility to form complex shapes. Most rotationally molded products on the market today are made using cast aluminum molds.

CNC Machined Aluminum Molds

Machined molds are milled from solid blocks of aluminum using CNC technology. They provide exceptional accuracy, tight tolerances, and smooth finishes. While more expensive to produce than cast aluminum molds, CNC machined molds are ideal when precision and repeatability are top priorities.

Fabricated Sheet Metal Molds

These molds are produced through electroforming or fabricated from steel or aluminum sheet metal. They are typically used for specific applications where durability and cost balance are critical. Fabricated molds may not capture intricate detail as well as cast or CNC aluminum, but they are effective for certain large or simple parts.

Each mold type has unique advantages, but cast aluminum remains the standard for most projects due to its balance of cost, flexibility, and performance. From small containers to tanks measuring hundreds of gallons, cast molds provide the versatility needed for today’s complex designs.

Cast Aluminum Molds

Cast aluminum molds are the backbone of the rotational molding industry and account for the majority of tools in use today. Their popularity stems from the balance they provide between cost, durability, and design flexibility, making them a practical choice for a wide range of products.

One of the key strengths of cast aluminum is its ability to capture fine detail from the master pattern. This allows even small text, intricate textures, or precise curves to be faithfully reproduced in the final part — an essential feature for applications where product appearance matters. Foundries can also produce multiple molds from the same pattern, ensuring consistency from part to part and across production runs.

Performance is another area where cast molds stand out. The most commonly used alloy, 356 aluminum, offers excellent heat transfer, which reduces cycle times and promotes even wall thickness throughout the molded part. Its malleability also makes it easy to texture, polish, or modify as product designs evolve. This flexibility is especially valuable when small adjustments are needed without the expense of creating an entirely new tool.

Typical wall thickness for cast molds is around ¼” to ⅜”, providing strength while keeping the mold lightweight enough for efficient handling. Tolerances generally fall around ±0.005 in/in, though small dimensions may vary slightly. Lead times are relatively short, with many patterns completed in 1–2 weeks and molds ready in about 6 weeks for small to medium-sized parts.

From tiny components to large-scale storage tanks, cast aluminum molds are adaptable to almost any product size or geometry. Compared to CNC machined or electroformed molds, they are often the most economical option, delivering repeatable, high-quality results without excessive upfront costs. For manufacturers looking to balance performance with affordability, cast aluminum remains the go-to choice in rotational molding.

Production of Cast Aluminum Molds

Creating a cast aluminum mold is a multi-stage process that combines engineering precision with skilled craftsmanship. Each step is carefully controlled to ensure the mold delivers consistent, high-quality parts with minimal maintenance.

Through this detailed process, cast aluminum molds are engineered to deliver repeatable results, withstand production demands, and provide design flexibility for a wide range of parts.

On a Tight Timeline?

On a Tight Timeline?

We offer rapid tooling services to get your mold built fast — meaning less downtime and quicker transition from prototype to production.

We offer rapid tooling services to get your mold built fast — meaning less downtime and quicker transition from prototype to production.

Production of CNC Machined Aluminum Molds

CNC machined aluminum molds offer exceptional precision, tight tolerances, and smooth finishes, making them an ideal choice for applications requiring high accuracy and consistency. The production of CNC machined aluminum molds combines advanced technology with skilled craftsmanship, resulting in high-quality, reliable tools that produce parts with excellent detail.

Process Overview

The production of CNC machined aluminum molds begins with the creation of detailed product designs, often communicated through 2D or 3D CAD files. These designs are reviewed by engineers to assess any potential issues that might arise during the molding process. Once the design is finalized, it is sent to the CNC machining process.

Steps in CNC Machined Aluminum Mold Production:

Advantages of CNC Machined Aluminum Molds:

- Precision: CNC machining provides unparalleled accuracy and tight tolerances, making it ideal for products requiring exact specifications.

- Smooth Finishes: The process results in molds with smooth surfaces, which are essential for creating high-quality, visually appealing parts.

- Consistency: CNC machined molds offer excellent repeatability, ensuring each part produced is identical in appearance and performance.

- Design Flexibility: CNC machining allows for the creation of complex geometries, intricate details, and undercuts that may not be achievable with other mold-making methods.

Applications:

- Automotive parts

- Consumer electronics

- Aerospace components

Production of Sheet Metal Fabricated Molds

Sheet metal fabricated molds are a versatile and cost-effective solution for rotational molding applications that require durability and precision but are less complex than those made from aluminum or CNC-machined materials. These molds are commonly used for producing large parts, simple designs, and parts with low to medium-volume production runs. The process of creating sheet metal fabricated molds combines skilled craftsmanship with advanced manufacturing techniques, ensuring the molds are ready for high-quality part production.

Process Overview

The production of sheet metal fabricated molds involves several key steps, from initial design and material selection to assembly and testing. While not as intricate as CNC-machined molds, sheet metal molds are strong, reliable, and often the most affordable option for parts with simpler geometries.

Steps in the Production of Sheet Metal Fabricated Molds:

Advantages of Sheet Metal Fabricated Molds:

- Cost-Effective: Sheet metal molds are generally more affordable to produce than their CNC machined or cast aluminum counterparts, making them ideal for lower-volume production or simpler designs.

- Speed of Production: The fabrication process is quicker than other methods, which can be especially beneficial for tight production timelines.

- Durability: While not as resistant to wear as some other mold types, sheet metal molds are still durable enough to withstand medium-volume production and are excellent for products with low to moderate complexity.

- Ease of Modification: Modifying sheet metal molds is relatively simple compared to more complex mold types, allowing for quick design changes.

Applications:

- Large, simple rotationally molded parts such as tanks, bins, and containers.

- Products requiring medium-volume production with less complex shapes.

- Applications where cost is a primary factor, such as for testing new designs or prototypes.

Permanent Coatings

Permanent coatings are an important step in preparing a mold for long-term use. These coatings not only provide consistent part release but also influence the appearance and surface finish of the molded product. By selecting the right coating, manufacturers can reduce maintenance, extend mold life, and achieve the desired aesthetic — from high-gloss shine to a soft matte texture.

In rotational molding, permanent coatings are typically applied after the mold has been cast, machined, and finished. They help control heating efficiency, protect the mold surface, and minimize operator-applied release sprays, which can add variability to the process.

Some of the most widely used coatings in the industry include:

- High-Gloss Finishes: Provide fast release and a smooth, polished appearance. Often used when the final product requires a premium look.

- Matte Finishes: Deliver a more subdued surface while still ensuring reliable part release. These are common in applications where glare or shine is undesirable.

- Semi-Gloss Finishes: Offer a balance between gloss and matte, giving parts a uniform and professional appearance.

- Exterior Mold Coatings: Applied to the outside of molds and spiders to improve heating performance and reduce corrosion.

Industry examples of permanent coatings include the Stonekote series, such as:

- Stonekote 7000: Bright green, high gloss, fast release.

- Stonekote 1000: Olive green, matte, slower release.

- Stonekote 5000: Black, semi-gloss, medium release.

- Stonekote 3000: Brown, matte, medium release.

- Stonekote 85: Black exterior coating to improve heating and reduce spider corrosion.

By matching coating type to the part’s functional and aesthetic needs, rotational molders can optimize both performance and appearance while reducing downtime for mold maintenance.

At Integrity Rotational, we understand that selecting the right tooling is a critical step in the manufacturing process. Whether you’re deciding between cast aluminum, CNC machined, or sheet metal fabricated molds, our team is here to guide you through every decision. We take the time to understand your design, production needs, and budget to ensure that you get the most cost-effective, durable, and efficient tooling solution. With our extensive expertise in rotational molding, we’ll help you make an informed choice that maximizes your production efficiency and product quality.

Reach out today to consult with us on your tooling requirements and let us help bring your designs to life with the perfect tools for the job.