The Rotomolding Process Overview

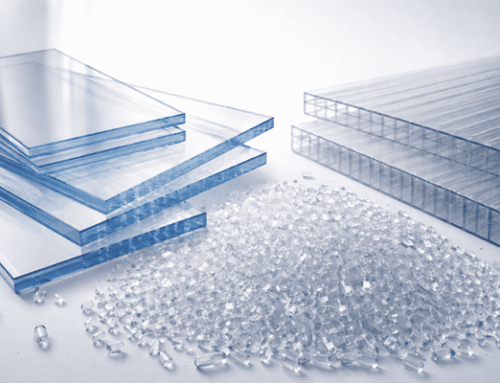

Rotational molding, or rotomolding, is a manufacturing process used to produce strong, seamless hollow plastic parts. The process begins when a measured amount of powdered resin is placed into a hollow mold. This mold is then bi-axially rotated in an oven, allowing the resin to evenly coat the interior surfaces as it heats and melts. Once the resin fuses and cures, the mold is cooled and the finished part is removed.

This method offers several advantages over other plastics processing techniques. One of the most notable is scale. Rotomolding equipment is capable of producing parts ranging from small components to massive items such as storage tanks, playground equipment, or even boat hulls — all in a single piece without seams or welds. The ability to produce extremely large parts in one cycle sets rotational molding apart from processes like injection or blow molding.

Design flexibility is another key benefit. Complex geometries, undercuts, and multi-wall designs can be achieved without the need for multiple components or costly assembly. Because the tooling is relatively lightweight and stress-free, molds are less expensive to produce and can be modified with greater ease. This makes rotomolding a cost-effective option for prototyping as well as full-scale production.

The process also naturally reinforces high-stress areas. Unlike injection molding, where corners may thin, rotomolded parts tend to build extra material in edges, ribs, and corners, enhancing durability. Combined with uniform wall thickness, this results in products that are both tough and reliable, making the process a preferred choice across industries such as automotive, marine, industrial, and consumer goods.

Advantages of Rotationally Molded Parts

The Rotational Molding Process With Integrity

At Integrity, we believe that the best part design begins with knowledge. By educating customers on the true capabilities of rotational molding and proactively addressing potential challenges, we help prevent costly revisions and unnecessary tooling expenses. Our commitment to transparency and collaboration ensures every project is designed for manufacturability from the start—delivering durable, efficient, and cost-effective solutions that stand the test of time.