Understanding Rotational Molding Plastic Compounds

Rotational molding plastic compounds form the foundation of every high-quality molded product. Each compound must perform consistently through the heating, rotation, and cooling phases that define the rotomolding process. Unlike injection or blow molding, which use pellets, rotational molding relies on materials pulverized into a fine powder—typically around 35 mesh—to ensure even wall thickness, seamless surfaces, and balanced strength.

Only select thermoplastics meet these demanding standards. Materials such as polyethylene, polypropylene, nylon, and polycarbonate offer varying levels of stiffness, impact resistance, and temperature tolerance. Additives like UV stabilizers and antimicrobial agents further enhance performance for outdoor, chemical, and food-grade applications. Selecting the right combination of resin and modifiers determines how a part functions, how long it lasts, and how efficiently it can be produced.

Polyethylene (PE): The Cornerstone of Rotomolding Materials

Among all rotational molding plastic compounds, polyethylene (PE) is the most widely used—and for good reason. Its versatility, durability, and cost-efficiency make it ideal for products ranging from waste containers and tanks to industrial equipment and safety components.

Polyethylene belongs to the polyolefin family and is available in several grades, each offering a unique balance of density, flexibility, and resistance:

- LLDPE (Linear Low-Density Polyethylene): Excellent impact resistance and flexibility. Common in outdoor furniture and industrial tanks.

- MDPE (Medium-Density Polyethylene): Balances stiffness and toughness, suitable for storage products and molded housings.

- HDPE (High-Density Polyethylene): High stiffness, strength, and chemical resistance; used for agricultural and water tanks.

- LDPE (Low-Density Polyethylene): Lightweight and flexible; ideal for consumer goods and specialty parts.

- XLPE (Cross-Linked Polyethylene): Chemically cross-linked for added toughness, tear resistance, and heat tolerance.

PE’s compatibility with additives and pigments makes it one of the most customizable rotomolding materials. Integrity Rotational Molding uses certified prime virgin PE for consistent melt quality, color uniformity, and long-term durability. Whether producing a prototype or a high-volume order, polyethylene remains the trusted foundation for quality rotomolded products.

Other Rotational Molding Materials and Compounds

While polyethylene dominates the market, several other rotational molding plastic compounds offer specialized performance advantages. These materials let manufacturers tailor stiffness, flexibility, heat tolerance, and appearance to meet specific application needs.

- Polypropylene (PP): Offers outstanding chemical resistance and rigidity. Ideal for food-industry products, autoclave-safe components, and abrasion-prone environments.

- Nylon (Polyamide / PA): Provides exceptional strength, impact resistance, and heat stability. Common in fuel cells, chemical tanks, and HVAC ducts.

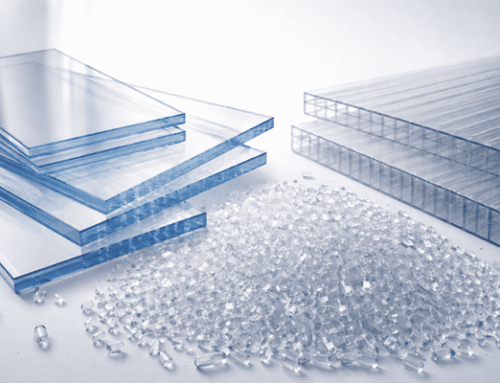

- Polycarbonate (PC): Known for its high impact resistance and clarity. Used in lighting enclosures, furniture, and protective housings that require transparency and toughness.

- Polyvinyl Chloride (PVC): Can be produced in flexible or semi-rigid forms, offering a wide hardness range. Common in toys, planters, and consumer products requiring softness and resilience.

- EVA Co-Polymer (Ethylene Vinyl Acetate): A flexible, rubber-like thermoplastic with excellent UV and low-temperature performance. Ideal for outdoor, sports, and water-resistant products.

Each material demands precise formulation and process control. At Integrity Rotational Molding, engineers select compounds based on performance goals, ensuring every part meets its functional and environmental requirements.

Choose the Right Plastic Compound

Choose the Right Plastic Compound

With expertise in polyethylene, nylon, and other advanced resins, we’ll help you pick the compound that matches your durability, weight, and chemical-resistance needs.

With expertise in polyethylene, nylon, and other advanced resins, we’ll help you pick the compound that matches your durability, weight, and chemical-resistance needs.

Additives and Color Blends in Rotational Molding Compounds

Additives and color blends can dramatically enhance the performance and longevity of rotational molding plastic compounds. These modifications improve durability, extend product life, and ensure consistent aesthetics—all without compromising structural integrity.

Common additive options include:

- UV Stabilizers: Prevent fading and degradation in outdoor applications.

- Antioxidants (AO Packages): Protect material strength and color during processing.

- Antimicrobial & Antifungal Agents: Inhibit bacteria and mold growth in sanitation or food-related products.

- Color Pigments: Provide consistent, custom colors for branding or identification.

- Impact Modifiers: Boost flexibility and crack resistance for heavy-duty parts.

Choosing the Right Compound with Integrity

Selecting the right rotational molding compound ensures the proper balance of strength, flexibility, and cost for your product. Each material offers unique benefits, and understanding these differences helps guarantee long-term reliability.

| Compound | Key Properties | Common Applications |

|---|---|---|

| LLDPE | Flexible, impact-resistant, easy to mold | Tanks, outdoor furniture |

| HDPE | Strong, stiff, chemical-resistant | Agricultural tanks, docks, containers |

| XLPE | Highly durable, tear and heat-resistant | Chemical tanks, duct work, waste systems |

| PP | Rigid, abrasion-resistant, food-safe | Food processing containers, autoclave components |

| Nylon (PA) | Strong, heat- and chemical-resistant | Fuel cells, HVAC ducts, industrial housings |

| PC | Transparent, high-impact, heat-resistant | Light fixtures, covers, safety shields |

| PVC | Flexible or semi-rigid, customizable hardness | Toys, planters, flexible consumer goods |

| EVA | Soft, elastic, UV-resistant | Outdoor, sports, and water-resistant products |

At Integrity Rotational Molding, our engineers collaborate with customers to match every material’s characteristics to its intended use. Whether you’re designing for durability, visual appeal, or cost efficiency, Integrity provides the expertise to help you choose the compound that meets your goals.